In demanding industrial applications, valve performance and durability are critical. To maximise service life, manufacturers often turn to valves with an exotic alloy construction, producing entire valves from wear-resistant alloys. While effective, this approach is costly and time-consuming.

Weld overlays offer a practical alternative, providing targeted protection for key internal valve surfaces. They deliver comparable durability without the expense of Exotic alloy manufacturing.

In this article, we outline the purpose, benefits, and typical applications of weld overlays in valve engineering, and why they’ve become the cost-effective choice across sectors including oil and gas, petrochemicals, and clean power generation.

What is a weld overlay?

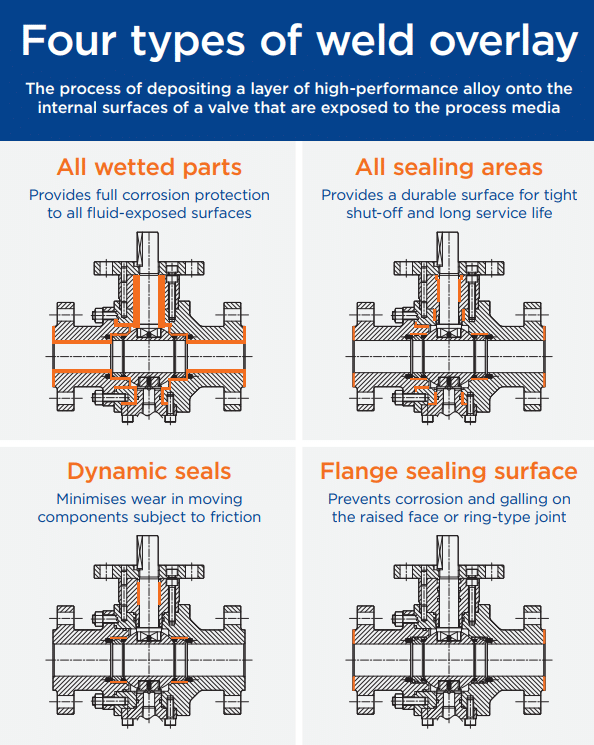

A weld overlay deposits a high-performance alloy onto internal valve surfaces exposed to process media – often called ‘wetted parts’. Commonly treated areas include:

- Seat pockets and sealing faces

- Stem or trunnion contact zones

- Flange sealing surfaces

- The entire internal bore (for fully clad valves)

Applied using techniques such as gas tungsten arc welding (GTAW) or Metal inert Gas (MIG), the overlay forms a robust metallurgical bond. The base valve body, typically carbon or low-alloy steel, retains its mechanical strength while the overlay resists corrosion, erosion, and mechanical wear.

The role of weld overlays in valve performance and affordability

Valves in process-critical environments face aggressive media such as sour gas, chlorides, acids, and abrasive slurries, which can quickly degrade untreated components.

Full exotic alloy valves solve this but at a premium cost. Weld overlays, by contrast, strengthen only the areas that need protection, offering many of the same longevity benefits at lower cost. Key advantages include:

- Enhanced corrosion resistance in sour or offshore conditions.

- Improved wear performance in dynamic sealing and moving parts

- Consistent sealing integrity over prolonged cycles

- Reduced maintenance frequency and cost

For many operators, overlays mean longer valve life and measurable savings.

Overlay applications in valve engineering

Flange sealing surfaces

Maintain sealing performance and prevent galling or pitting in corrosive or high-pressure environments.

Sealing components

Hardfacing overlays such as Stellite improve wear resistance and maintain shut-off performance.

Dynamic seal areas

Protect O-ring grooves and seal housings in stem or trunnion areas, reducing wear from actuation and extending service life.

Fully clad interiors

Provide a continuous barrier in highly corrosive services, preventing base material degradation.

Material selection for overlays

Material choice depends on process media, mechanical demands, and operating temperatures. Common options include:

- Alloy 625 – High corrosion resistance, ideal for sour service and offshore use

- Stellite – Hardfacing alloy for wear resistance in sealing areas

- 316L stainless steel – General corrosion protection in moderate conditions

- Tungsten carbide – For severe erosion and high-velocity flow environments

This selective approach ensures durability without unnecessary cost.

Overlay vs full exotic valve construction

Exotic alloy valves provide uniform corrosion protection but at significantly higher cost and longer lead times, which may not suit tight schedules or urgent maintenance. They can also complicate like-for-like replacements in older or bespoke systems.

Weld overlays deliver comparable surface protection where it’s needed most, allowing the use of more economical base materials. Advantages include:

- Lower material and production costs

- Shorter manufacturing and delivery times

- Targeted protection tailored to service conditions

- Greater design flexibility without compromising durability

This balance of longevity and affordability makes weld overlays ideal for both new valve projects and refurbishment.

Conclusion

Weld overlays offer a reliable, efficient way to improve valve durability, sealing performance, and lifecycle cost. By reinforcing only the surfaces exposed to process media, they provide essential protection without the financial or logistical burden of full-alloy fabrication.

For asset operators, engineers, and procurement teams seeking performance, longevity, and value, weld overlays present a robust engineering solution aligned with modern operational demands.